3D Printing Photography Parts on the Fly

From time to time we need to 3d Printing Photography Parts on the Fly, either for our equipment or for our riggings. This post is going to be about the trigger button that I have used for years on the medium rig.

Back in 2004, I built this rig out of necessity for 3d product photography. You could not just run out and find an indexed turntable that you could use for photography. Trust me, I tried. We had a few companies at the time that created turntables, but the cost was prohibitive for a young 360 photography company. I figured I could build a better option for my needs. Anyways, the turntable was the easy part. The trigger that was used to make the turntable move was another issue. I needed a switch, and that was about it. In the shop, I found a few pieces that would be the job. A piece of wood and a doorbell! Little did I know that I would be using that trigger for almost 20 years.

Lets start 3d Printing Photography Parts

Finally, we got a new toy in the studio, a little 3d printer, and I could upgrade the trigger.

The first thing I needed to do was find a new button. Being a child of the ’80s, I knew what button I wanted, an arcade button. After a quick search of the internet, I found a source for a 6 pack of buttons, the idea was on.

The first thing I needed to do was find a new button. Being a child of the ’80s, I knew what button I wanted, an arcade button. After a quick search of the internet, I found a source for a 6 pack of buttons, the idea was on.

Designing for 3d Printing Photography Parts

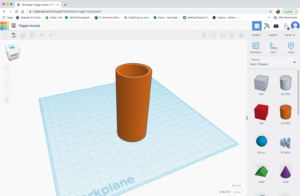

Next, I jumped over to Tinkercad and I drew the button holder out. Nothing fancy, just a cylinder, with a lip on the top and a hole at the bottom for the wire to hang out. I did need to use a caliper to make sure that the sizes were all correct.

Next, I jumped over to Tinkercad and I drew the button holder out. Nothing fancy, just a cylinder, with a lip on the top and a hole at the bottom for the wire to hang out. I did need to use a caliper to make sure that the sizes were all correct.

As a side note, this crazy 3d printer has started making me think about the metric system of measurement for small items!

Lets slice the .stl file

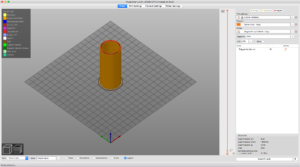

Once the tube was drawn, I needed to export the file as a .stl file so that I could open it up in PrusaSlicer. This makes it to where I can edit the “Print Settings” for the file. It sets the height of the lines, the width of the filament, and the speed of the printer. It also “Slices” the file so that the printer can build the prototype.

Once the tube was drawn, I needed to export the file as a .stl file so that I could open it up in PrusaSlicer. This makes it to where I can edit the “Print Settings” for the file. It sets the height of the lines, the width of the filament, and the speed of the printer. It also “Slices” the file so that the printer can build the prototype.

Time to Print or Photography part in 3d

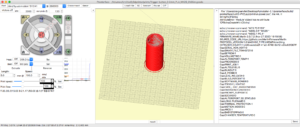

On to Pronterface for the printing!!! This is the fun part, you get to watch your idea start on the computer, and line by line it comes out into the real world. This is really like watching one of those cartoons where art comes to life. Three hours later, the part is born, and now it is time to wire this thing up.

On to Pronterface for the printing!!! This is the fun part, you get to watch your idea start on the computer, and line by line it comes out into the real world. This is really like watching one of those cartoons where art comes to life. Three hours later, the part is born, and now it is time to wire this thing up.

I had built this piece so that the button fits perfectly from the top as a slide in, the wire can be pulled in from the bottom, and a knot is added to the original wire so that it can not get pulled through. I felt it was an easy design and will last for another 20 years.

The buttons that I ordered did come with pigtails and I chose to solder the pigtail to the wire from the rotator. I thought this might help with the life expectance of the trigger.

In the real world

Here it is after assembly. Nothing crazy, but a world of difference from the original design to the finished product.

What is next

Now that I have printed photography parts with the 3d printer, next up, an Arduino interface between the turntable and the camera.

Leave a Reply

Want to join the discussion?Feel free to contribute!